JSL STAINLESS LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to JSL STAINLESS LTD.

Ferro Alloys

In the first phase of the Odisha project, JSL has set up Captive Power plants, Coke Oven batteries and Ferro Alloys.

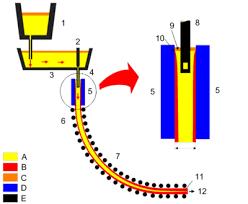

Ferro Alloys has set up of submerged arc furnaces 2 X 60 MVA supplied by M/s SMS DEMAG AG & 3 X 27.6 MVA supplied by M/s Sibelectrotherm with a production capacity of 250,000 ton per annum High Carbon Ferro Chrome. All these furnaces are user friendly and capable of producing any Ferro Alloy.

The waste heat of 2 X 60 MVA furnaces are utilized to generate 13MW power.

The infrastructure is made to send liquid Ferro Chrome directly from 2 X 60 MVA furnaces to SMS.

As the Chrome ore is mostly available in the form of friable in nature the plant is supported with two agglomeration Briquetting units of 66 TPH supplied by Maschimemfabrik KOPPERN, Germany & 30 TPH of Indegenous make.

For a good metal recovery the plant is supported with Jigging Plant of capacity 1 X 50 TPH, 1 X 7.5 TPH, 2 X 10 TPH & 1 X 10 TPH Sludge beneficiation plant.

The plant is equipped with modern de-dusting for pollution control and waste management systems.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.